4life technology

- Roughing Inserts

- Cutting Fractionation

- Double clearance cutting edge

- Cutting edge with NaDia DLC coating

TECHNICAL ADVANTAGES

4Life has been designed and tested to overcome all the technical issues which are present in the different processing stages. In every technical specification, from designing to assembling the inserts, 4Life represents a revolution in the techniques and technologies of industrial cutting.

EFFECTIVENESS

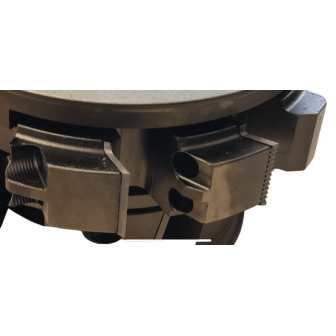

Roughing insert combined with the finish insert

The share cut reduces considerably the loads on the engine shaft. The particular cutting angle and the reduced distance between the cutting edges, prevents effectively the micro-vibrations of the tool, preserving the product working process. The special assembly of the inserts limits the chipping during the tenoning and scribing process, ensuring an excellent finish across the grain.

PRECISION AND DURABILITY

Double rake grinding inserts with NaDia diamond coating

The double rake grinding reduces the cutting wear due to the contacting at the critical phase of the wooden chip removal. Thanks to the particular Tct micro-grade carbide combined with the quality of the grinding process, allow us to have a high performance cutting edge. NaDia coating extends the initial cutting quality to many meters compared with what obtained from the same uncoated inserts, reducing replacements of the roughing inserts to once every 4 maintenances.