Kompressor EUROAIR 410/10/50 D

Kompressor EUROAIR 410/10/50 D

Kompressor EUROAIR 410/10/50 D

Svars:

58 kg

Pieejamība:

Uz pasūtījuma

Zīmols:

ELMAG

Preces kods:

DT2080064220 953,48 €

Ar PVN /

Product Highlights

You will find more details about WERKER, BOY and EUROAIR mobile compressor series here: WERKER, BOY and EUROAIR mobile compressor seriesTechnical Facts

- Plug-and-play' - equipped with two quick-connect couplings

- CONDOR pressure switch for automatic on/off operation

- Motor-protective circuit-breaker

- Tank and system pressure gauges

- Filter pressure reducer model FR 1/4'

- Safety valve

- Non-return valve

- Ball valve for condensate drain

- Single-stage two-cylinder compressor with 230 volt engine

- 50 litre container volume

- Aggregate speed ONLY 930 rpm

Substitute

This article could be an alternative for you:Specifications

Effective delivery amount

240 l/min

Delivery quantity according to VDMA 4362, measured at 80% of the maximum pressure

Yes

Suction power

400 l/min

Max. operation pressure

10 bar

Oil lubricated

Yes

Container volume

50 l

Motor nominal power

2.2 kW / 3 PS

electrical connection voltage / frequency

400 V / 50 Hz V/Hz

Sound pressure level (4 m)

75 dB(A)

rotational speed compressor

1.01 rpm

Length

86 cm

Width

42 cm

Height

84 cm

Weight

58 kg

First-class professional entry-level model

EUROAIR 310, 330, 400 and 410 air compressors from ELMAG are outstanding entry-level models in the professional class. Their excellent value for money also makes them suitable for the discerning home improvement enthusiast.These powerful units with AC or three-phase motor, V-belt drive, cast cylinder, precision high-performance piston, large fan wheel and post-cooling system made of die-cast aluminium (EUROAIR 400 and 410 only) provide sufficient compressed air even for extended delivery of power. For smaller painting jobs, too, sufficient reserves of compressed air are always available.The low engine speeds of ONLY 930 to max. 1,450 rpm provide a high duty cycle, long life and smooth operation.Great performance - low price: EUROAIR!Intake capacity

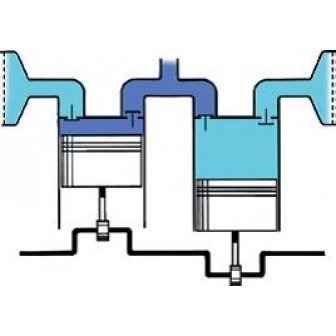

The intake capacity is calculated from the cylinder volume and the speed of the compressor.Crucial in the selection of a compressor, however, is the effective delivery quantity.Piston compressor technology

A piston compressor consists of one or more cylinders with pistons driven by a motor. The air is sucked into the cylinder and compressed in one or more steps to the operating pressure. After compression, the compressed air flows through the aftercooler to the compressed air tank.Oil-lubricated or oil-free compression?

The cylinders, pistons and cranks of an oil-lubricated compressor are lubricated with oil that circulates in the compressor. The compressed air of an oil-lubricated piston compressor contains some residual oil, usually 10-15 mg/m3. Most versions of oil-free piston compressors have permanently lubricated bearings. The pistons have grease-free piston rings, usually made of Teflon or carbon fibre. Replacement of bearings and piston rings is usually required more frequently with this type of compressor than with oil-lubricated versions. However, the compressed air is free of oil residues.Applications

Piston compressors are particularly suitable for lower compressed air requirements: single-stage compressors for pressures up to approx. 8-10 bar,multi-stage versions can deliver up to 30 bar.They should only be used temporarily. The capacity utilisation of anair-cooled piston compressor may not exceed 60%. After compressing for2 minutes, the compressor must rest for at least 1.5 minutes. The total compression time per day should be limited to a maximum of approx. 4 hours.