Hydraulische Abkantpresse 3-Achsen Mod. CNC-HAP 1270x40t

Hydraulische Abkantpresse 3-Achsen Mod. CNC-HAP 1270x40t

Hydraulische Abkantpresse 3-Achsen Mod. CNC-HAP 1270x40t

Svars:

3050 kg

Pieejamība:

Uz pasūtījuma

Zīmols:

ELMAG

Preces kods:

DT2035602956 48 945,00 €

Bez PVN /

Product Highlights

You will find more details about Hydraulic press brakes - CNC HAP here: Hydraulic press brakes - CNC HAPTechnical Facts

- High quality standards

- Robust industrial models with high edge accuracy based onstate-of-the-art production

- Welded, tension-free monoblock steel constructionwith very good vibration damping

- S275 material with very high tensile strength

- High-quality BOSCH-REXROTH or HOERBIGER hydraulic systemwith precise proportional valve technology

- Powerful hydraulic cylinders, honed and chrome-plated

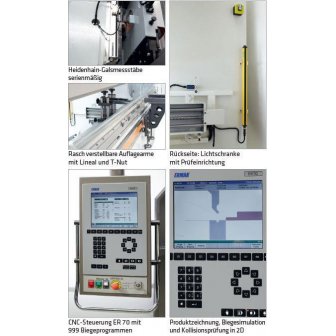

- CNC control ER 70 with 2D graphical display and bending simulation

- Y1/Y2: CNC-controlled vertical axes with automatic positioning on linear scales, synchronisation tolerance ± 0.01 mm

- X: CNC-controlled backgauge, AC drive with ball screw, linear guide tolerance of backgauge fingers ± 0.01 mm

- Bending tool made of high-alloy, hardened special steel

- Individual models with crowning device

- Control cabinet with cooling system, SIEMENS electrical components

- CE safety devices

- Safety built in with side gap cover

- Light barrier on the back of the machine

- Emergency stop button on the control unit and on the operating column

- Easy handling

- Upper tool holder with PROMECAM quick-change system

- Upper tool made of easily replaceable standard segments 835 mm

- Lower tool 60x60 with four V-bending channels

- Ergonomic, swivel control panel CNC HAP

- Adjustable support arms with ruler and T- slot

- Mobile operating column with foot release

Substitute

This article could be an alternative for you:Specifications

Bending length

1.27 mm

bending capacity

40 t

cambering WILA manually

-

CNC cambering WILA motoric

-

speed x-axis servo drive

230 mm/s

traverse r-axis

250 mm

speed r-axis servo drive

180 mm/s

rapid traverse Y axis

140 mm/s

speed y-axis

17.0 mm/s

retraction y-axis

170 mm/s

X axis travel

800 mm

speed X-axis AC-engine

230 mm/s

backgauges

2 Num.

support arms

2 Num.

motor power

5.5 kW

distance between tie bars

1.05 mm

Stroke

170 mm

Built-in height

387 mm

Overhang length

350 mm

Desk height

850 mm

Desk width

90 mm

Length

2.15 mm

Height

2.3 mm

Width

1.65 mm

oil tank volume

80 l

Weight

3.05 kg

From extra lightweight to heavy

Depending on the model, CNC HAP press brakes offer a bending capacity of 40 to 400 tons and a bending length of 1,270 to 4,100 mm.Maximum dimensional stability

CNC HAP press brakes are high-performance machines with precise synchronization and proportional valve technology. They meet the highest demands on the parallelism of the bending tools and offer very high dimensional stability. The synchronization and linear guidance tolerance of the machine axes is only ± 0.01 mm.Fast X-axis, R possible

CNC HAP models come with three automatically controlled axes as standard. The vertical axes (Y1, Y2) are positioned hydraulically. The backgauge (X) is moved by an electric motor with a speed of 230 mm/s. Two preciseball screws ensure very accurate positioning. As an option, a fourth machine axis (R) with fast-running servo drive is also available.CNC ER 70

Thanks to modern control technology, CNC HAP models are very easy to use. A total of 999 bending programs and 99 bending step repetitions enable rapid and flexible individual parts and series production.Single models with crowning

Individual CNC HAP models are equipped with a manual or motorised adjustable crowning device to correct angular deviations. Optional extras such as special bending tools, pneumatic or hydraulic clamping systems, etc. allow expansion of the product functions.TECHNICAL INFO - Synchronised press brakes

For precise and continuous edging with accurate angles, even parallel lowering of the upper tool is required. This is achieved by two hydraulic cylinders Y1 and Y2, the strokes of which must be synchronized. With ELMAG® press brakes, synchronisation of the Y axes is achieved by means of high-precision CNC linear scales and CNC-controlled proportional valves. The synchronisation tolerance is only ± 0.01 mm.Standard features

- Upper tool segments hardened 835 mm special steel- Lower tool 60x60, four bending channels, special hardened steel- Upper tool holder with PROMECAM quick-change system- CNC-linear scales Y1/Y2- CNC-controlled backgauge, X-axis with AC drive- Individual models with crowning device- CE safety devices- Support arms with ruler and T-slot- Swivel control panel DELEM ER 70- CNC ER 70- Mobile operating column with foot release and emergency stop button- Operating instructions/CESpecial accessories

- WILA manual crowning- WILA motorised crowning, calculation according to compressive force- Dynamic two-axis backgauge X/R with servo drive- Hydraulic upper and lower tool clamping system- Pneumatic upper tool clamping system- WILA upper and lower tools- AKAS Laser Safe light barrier- Customised projection on request