Hydraulische Abkantpresse 3-Achsen Mod. ECO-BEND 2600x80t

Hydraulische Abkantpresse 3-Achsen Mod. ECO-BEND 2600x80t

Hydraulische Abkantpresse 3-Achsen Mod. ECO-BEND 2600x80t

Svars:

4557 kg

Pieejamība:

Uz pasūtījuma

Zīmols:

ELMAG

Preces kods:

DT2107117435 54 940,00 €

Bez PVN /

Product Highlights

You will find more details about Hydraulic press brakes - ECO BEND here: Hydraulic press brakes - ECO BENDTechnical Facts

- High quality standards

- Robust, state-of-the-art industrial models with high edge accuracy

- Welded, very stable and tension-free monoblock steel structure with very good vibration damping andhigh tensile strength to absorb the bending torque

- High-quality BOSCH-REXROTH or HOERBIGEr hydraulic system

- Precise proportional valve technology

- CNC linear scales, synchronisation tolerance ± 0.01 mm

- CNC control ER 70 with 2D graphical display and bending simulation

- Automatic positioning of Y-axes

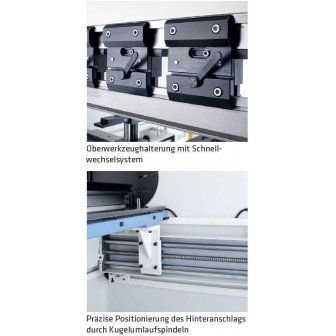

- X-axis backgauge system with AC motor/recirculating ball screw

- Precisely adjustable backgauge parallelism

- Linear guide tolerance of backgauges ± 0.01 mm

- Bending tools made of high-alloy, hardened special steel

- Projection 250 mm

- Control cabinet with cooling system, SIEMENS electrical components

- CE safety devices

- Integrated safety through side gap covers

- Light barrier on the back of the machine

- Emergency stop button on the control unit and foot switch

- Easy handling

- Upper tool holder with quick-change system

- Upper tool segments easily replaceable

- Lower tool with four V-bending channels

- Ergonomic, rotatable control panel

- Two support arms with T-slot, five adjustment positions

- mobile foot switch

Specifications

Bending length

2.6 mm

bending capacity

80 t

rapid traverse Y axis

90 mm/s

speed y-axis

7.5 mm/s

retraction y-axis

60 mm/s

X axis travel

500 mm

speed X-axis AC-engine

230 mm/s

backgauges

2 Num.

support arms

2 Num.

motor power

5.5 kW

distance between tie bars

1.6 mm

Stroke

160 mm

Built-in height

380 mm

Overhang length

250 mm

Desk height

800 mm

Desk width

90 mm

Length

3.75 mm

Height

2.3 mm

Width

1.95 mm

oil tank volume

150 l

Weight

4.557 kg

Economical bending

For cost-effective production of most bending parts, a light and precise press brake with three automatic drive axes is sufficient. The hydraulic vertical axes (Y1, Y2) must be exactly synchronized and the backgauge (X) should be equipped with a fast electric drive and precise ball screws.Customised bending capacity

The longer the bending parts are, the greater the bending capacity must be. ECO BEND models come with a bending capacity of 80 to 200 tons. With a bending length of 2,600 to 4,100 mm, they cover the needs of many metalworking companies. Powerful 5.5 to 11.0 kW drive units provide enough power for continuous serial use.The precision of a large model

With a synchronisation tolerance (Y1, Y2) and a linear guide tolerance of the back gauge (X) of only ± 0.01 mm in each case, ECO BEND models meet the highest demands in terms of the parallelism of the bending tools and accurate workpiece positioning.CNC

Programming of the vertical axes and the backgauge is very easy and quick on the swivel-mounted ER 70 CNC unit. 99 repetitive bending steps in series and automatic axis positioning are particularly time-saving features.High product safety

CE safety devices such as side guards, side gap covers and a light barrier on the back of the machine offer optimum safety. Other safety features are available as options.Crowning possible

A manual or motorised crowning device for pre-tensioning the lower tool with very high bending capacity is available as a special accessory.Application examples -

- Mechanical engineering - Control cabinet construction- Automotive workshops - Body construction- Metalworking shops- Plumbers- Installers- Insulation companies- Façade construction- Training workshopsSpecial accessories

- Manual crowning- Motorised crowning- SICK front light barrier- SICK V4000 camera protection system- DFS laser light barrier- AKAS laser protection system- Oil cooler (high-load operation)- Oil heater (cold operation)- Additional backgauge- Additional foot switch - WILA press brake tools